VIVA Composite Panel, Pantheerankavu, kozhikodeBuilding Materials Supplier in Pantheerankavu, Kozhikode, Kerala

INRhttps://connect.vivaacp.com/vivaacp/kozhikode/pantheerankavu/viva-composite-panel--JXycw5/home

INRhttps://connect.vivaacp.com/vivaacp/kozhikode/pantheerankavu/viva-composite-panel--JXycw5/homeNo 1/765-A, Manakadavu Road, Nearby Exicder Battry, Pantheerankavu, kozhikode, kerala - 673019

Category

View allProducts

View allVideos

View allReviews

Gallery

About Us

Request A Call Back

Payment Methods

Services

Tags

FAQ

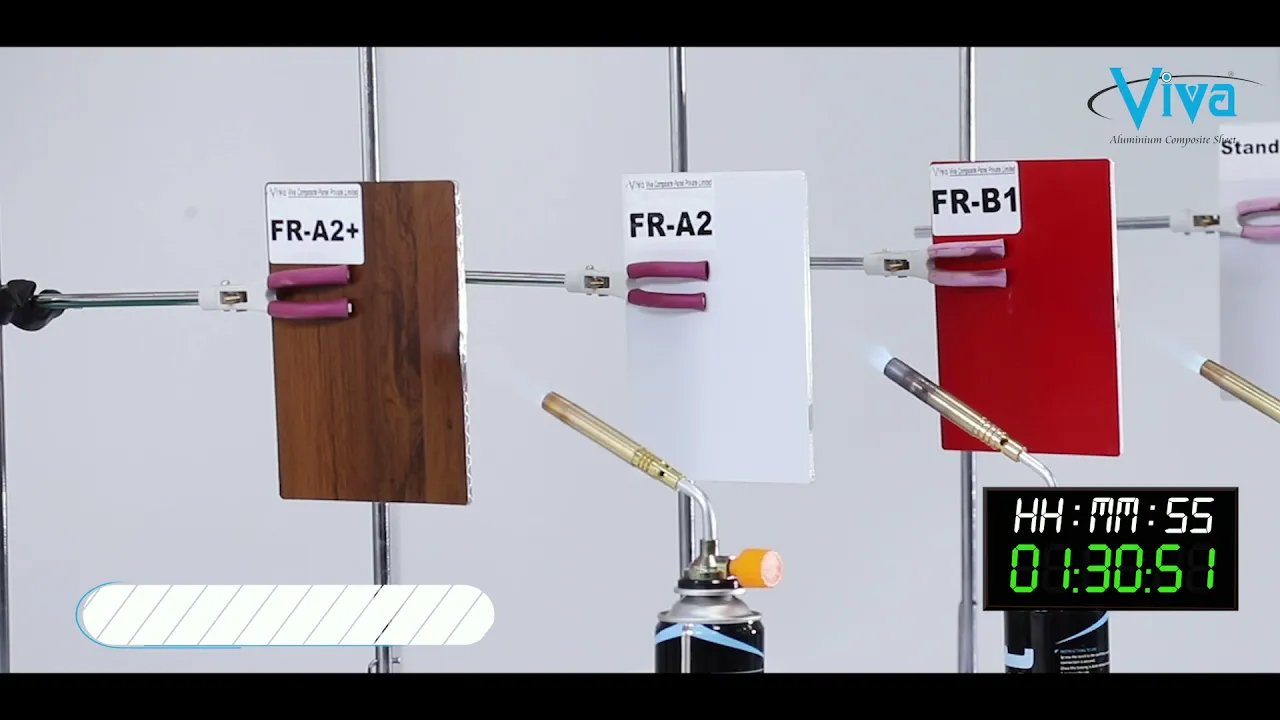

The term fire resistant refers to a material that is intended to withstand the heat of fire for a limited amount of time, for example, 2 hours or less. The purpose of fire-retardant materials is to burn slowly.

Yes, ACP is a Green Building material. It is because ACP panels are made of recycled materials such as aluminium, polymer, and minerals. Moreover, it is possible to recycle them easily without compromising their quality or value.

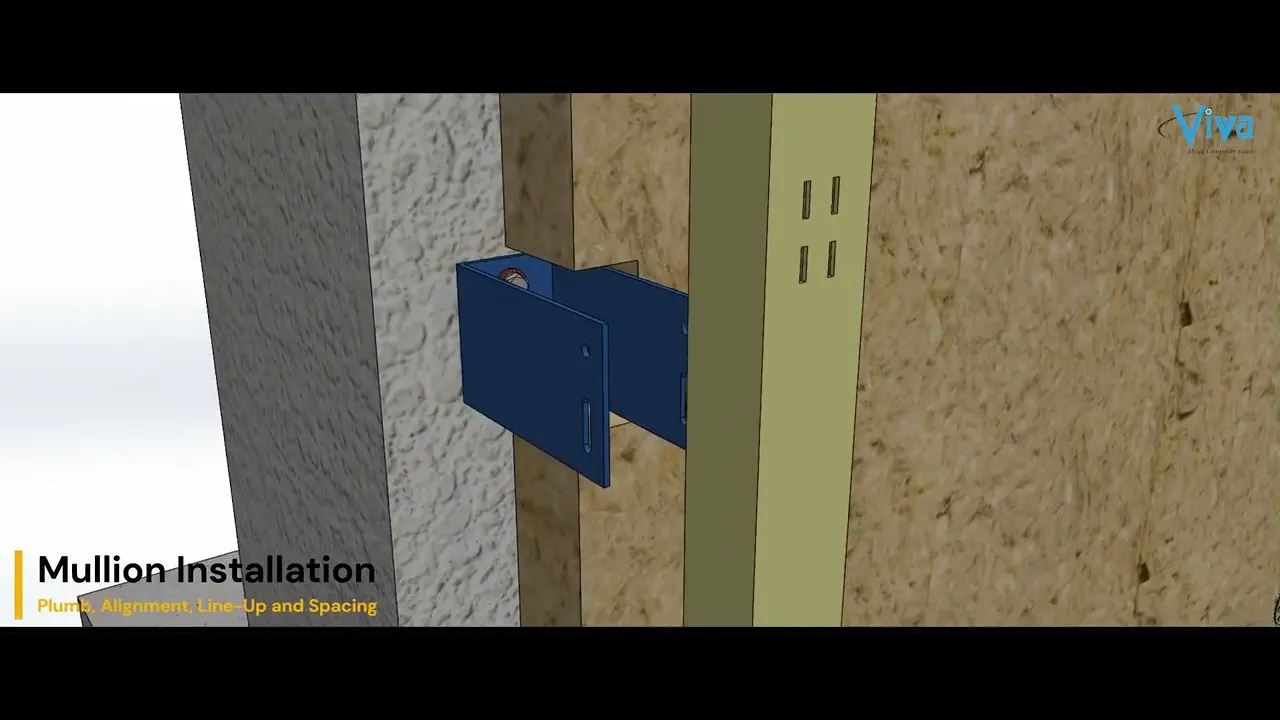

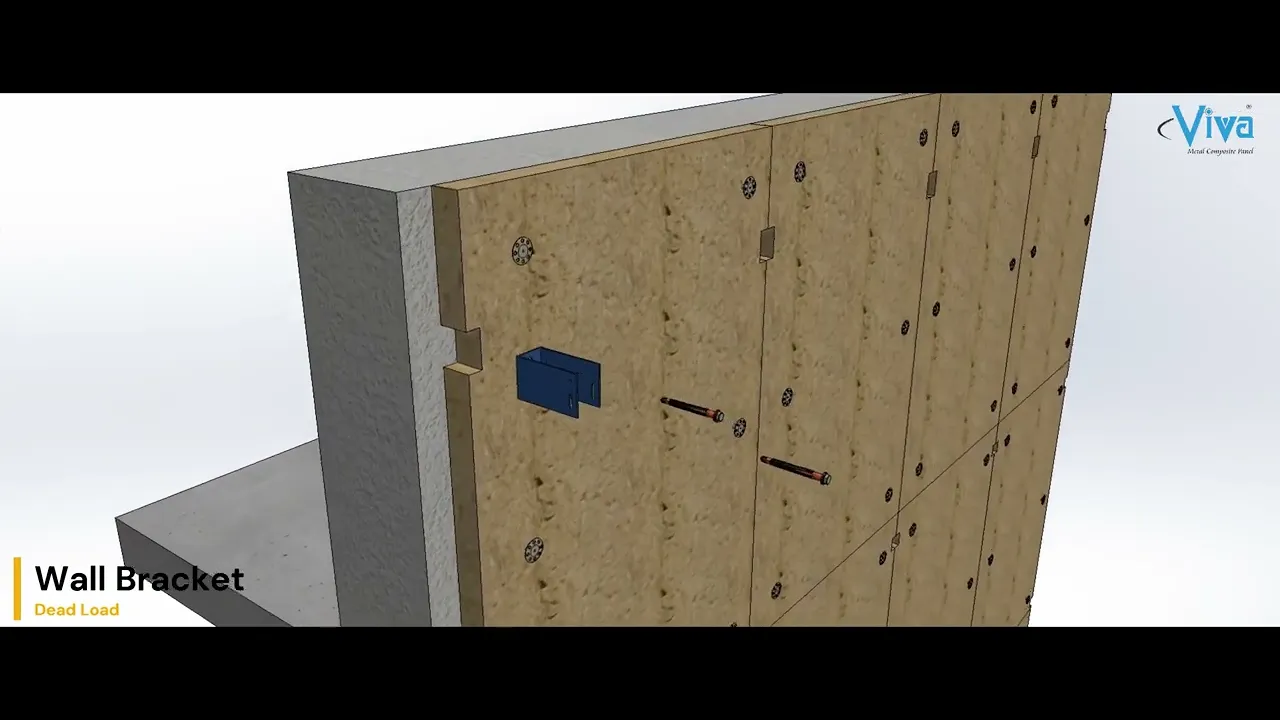

The two most used methods for fixing ACP panels are tray mounting and direct screwing.

To fill the gaps between the two ACP panels, Silicon is used. It has both exceptional adherence and UV resistance, making it ideal for exterior gap filling.

Following customized order make ACP –

a. ACP thickness – up to 10 mm.

b. Core type – Recycled/Virgin/mineral 70%/mineral 90%/3Dcorrugated core.

c. Core colour – White/black/Green etc.

d. Coating type – PE/SDPE/HDPE/PVDF/FEVE

e. Coating thickness – As per customer requirement (2 coat system ,3 coat sytem etc).

f. Aluminum alloy – 1100/3000/5000 series.

g. Coil thickness – 0.10/0.15/0.18/0.21/0.25/0.30/0.40/0.50/0.70 etc.

h. Surface protective film shelf life – 45/180 days.

i. Fire retardant – B1/A2/A2+

j. Fire rating – up to 2 Hrs.

Long life, light weight, weather-proof, high impact resistance, chemical resistant, corrosion resistant, rigid, fast installation, low maintenance and less dead weight on the building structure.

Due to their specially designed Nanotechnology-based coating, anti-scratch ACPs have a high gloss appearance and maximum scratch resistance against windstorms, earthquakes, cyclones, or abrasions. However, they are not 100% immune to scratches, marks and damage.

We use FEVE (Lumion)/ PVDF/ SDP based paint for exterior application and Polyester paint used for interior architecture (texture finish also).

Primarily, aluminum composite panel or ACP sheets meet the requirements of exterior applications like facade panels, column covers, display units, and canopies. They are a favourite construction material among builders and interior designers for trade show booths, hotels, shops, hospitals, corporate offices, apartments, villas, partitions, signage, machine coverage, pillar wraps, and false ceilings.

We use 70% KYNAR 500 certified PVDF (Fluorinated polyvinyl) paint which conforms to ASTM (American Society for Testing and Materials) and EN (European Nation) standards. KYNAR 500 is a registered trademark of Arkema Inc. Our paints are lead-free

Viva uses either an LLDPE(Virgin)core, LDPE core or Mineral core. In FR B product, the ratio of Mineral core and Organic content is maintained as 70:30 respectively.

ACP is the acronym for aluminum composite panels. They are layered panels made up of a thermoplastic or non-combustible core sandwiched between two aluminum sheets.